How TrapBags Are Made

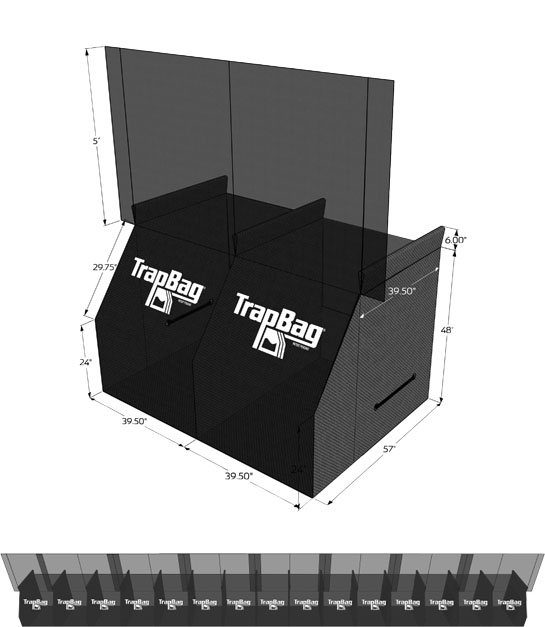

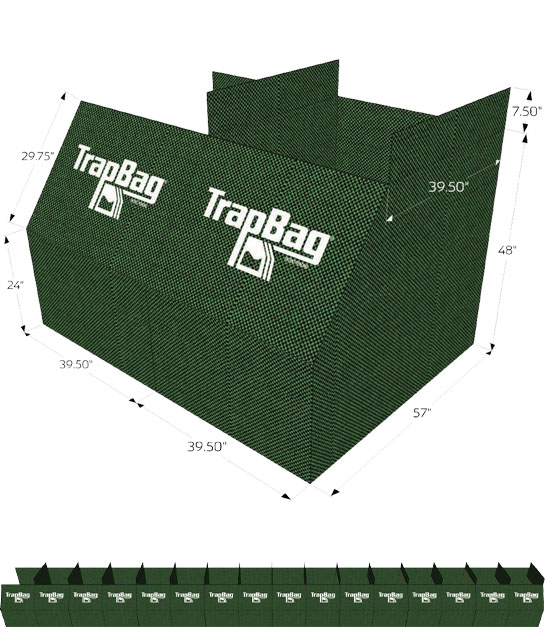

TrapBags are assembled with a high-strength polypropylene geotextile fabric, which is much more durable than traditional sandbags. They’re designed with a pentagonal shape for added mass in the bottom 50% of the barrier. This ensures that there is never a tipping point.

However, they’re also designed to be flat on top. That way, the bags can be stacked atop each other for taller flood protection or erosion barriers.

How TrapBags Are Deployed

From the very beginning, we designed TrapBags to be easy to deploy while still having the strength and flexibility for multiple different applications. You can set up your TrapBag barrier in just a few simple steps:

-

Open the packaging: TrapBags come in 50-ft sections and are folded up for packaging. Remove the TrapBags from the pallet and stretch the barrier up to 50 linear feet. If the total length of protection needed is greater than 50 ft, connect the multiple 50 ft sections.

-

Place or stack the barrier where needed: Place your base layer of TrapBags in a predetermined location.

-

PlaceFill the cells: A small crew with relevant equipment (front-end loader, skid steer, etc.) can fill the TrapBags quickly. We recommend filling the TrapBags with sand or gravel. Once the base layer is filled and installed, you can stack the TrapBags to create a higher barrier.

The Benefits of TrapBag

Efficiency

TrapBag saves money and time during every step of the process. Each barrier unit takes up very little space in storage and is easy to ship before you need it. Once you’re ready to use them, they require a fraction of the manpower and material of traditional sandbags. We designed them this way so that you can respond to emergencies more quickly than you would with sandbags.

Longevity

TrapBag flood barriers are designed to have a minimum lifespan of at least five years when exposed to the UV. They’ve also been proven to withstand anything Mother Nature throws at them, from mudslides and floods to coastal storms and constant wave action. Our bags have seen it all and continue to handle everything without hesitation.

Furthermore, our erosion control bags have an extra layer of fabric for added UV life. Using our proprietary formula, we’ve created a geotextile that lasts longer than any of its counterparts on the market—tests have shown it gets even stronger after the first 500 hours of UV exposure.

Whether you need short-term flood protection or long-term erosion control barriers, TrapBag® is an option that’s built to last.

Versatility

Our flood and erosion protection systems can be used across dozens of different types of projects, ranging from storm surge protection in coastal cities to chemical spill containment along rivers and streams. They’re designed to respond as quickly as you can, all while saving you time and funding when it matters most.

Flexibility

Whether you need a 2-foot barrier or a 4-foot one, we offer flood bags in multiple sizes that you can stack on top of each other. This gives you endless protection options. TrapBag also doesn’t require any special fill materials—just use sand or gravel for temporary barriers, or cement if you need a more permanent solution.

Our Products

Erosion Barriers

Erosion Barriers

TrapBag is designed to be used as a long-term erosion control barrier for protecting coastal, beachfront, and riverfront properties across the world. When placed against properties and sand dunes, they can prevent erosion from advancing any further.

Our erosion barriers come with lids, which you can install with hog rings and a hog ring gun, to prevent the fill material from escaping during wave action. This allows them to continue working for years to come with minimal amounts of damage.

Flood Barriers

Flood Barriers

Our flood barrier systems are designed to be deployed in a fraction of the time of regular sandbag retaining walls. TrapBag barriers come in lengths of 50 feet each and can hold back thousands of pounds of water pressure. They’ve even been successfully tested by the US Army Corps of Engineers, illustrating military-grade strength that makes them ideal for protecting everything that matters during hurricane storm surges, river floods, and beyond.

Cofferdam Bags

Cofferdam Bags

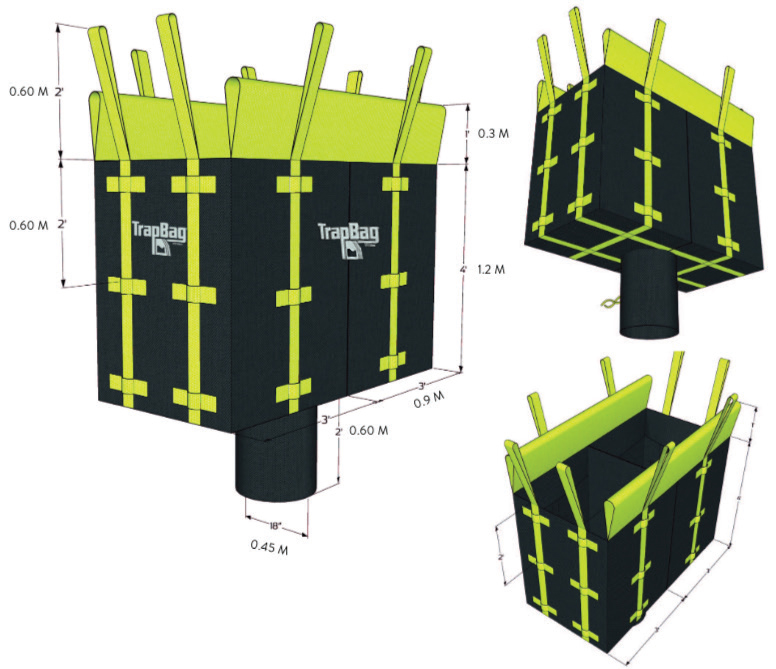

Cofferdams and other underwater structures require a different approach to keeping out water, so we changed our design just for these applications as part of our continuing efforts toward customization.

Unlike our standard TrapBags, our cofferdam bags are individual bags with an anchor point at the very bottom, rather than a chain of cells. They’re completely rectangular and don’t have slopes like their original counterparts. Each unit has rigid Coroplast panels to help the bag maintain its shape and prevent bulging. This way, they can be placed directly against each other to form a watertight seal.

You’ll need a spreader bar for your excavator or skid steer to lift these special bags into place. You may also want to add an HDPE liner to the water-facing side of your cofferdam to create a truly waterproof seal.

Fabric Forming System

Fabric Forming System

Designed for the most heavy-duty, long-term projects, our Fabric Forming System was made with concrete in mind. These barriers are made of heavy-duty material that allows you to fill the TrapBags with cement and act as a forming system. Stainless steel cables run through the center of the barrier so all of the concrete cells are tied together. Once the concrete cures, you can remove the TrapBag material with a razor knife, and any excess material can be burned off with a torch. The Fabric Forming System is great for seawall or retaining wall projects where a permanent solution is needed.